The Best Guide To Conway Concrete Company Concreters

The smart Trick of Conway Concrete Company Concrete Foundation That Nobody is Discussing

Table of ContentsWhat Does Conway Concrete Company Concreters Mean?Not known Details About Conway Concrete Company Concrete Driveway The Best Strategy To Use For Conway Concrete Company Concrete SlabTop Guidelines Of Conway Concrete Company Concrete Patio

consist of properly produced videos shown by exercising craftspeople, and auxiliary downloads like tests, blueprints, and various other products to aid you understand the abilities.

Concrete is solid inside as well as beautiful exterior. Concrete is a composite structure material made by combining cement (usually Rose city concrete), water, rugged aggregates, as well as fine aggregates.

Just how several kinds of concrete remain in use? This message will aid you pick the kind of concrete that is right for your building project. The history of concrete returns to 6500 BC when the Nabataea investors in the regions of Syria and Jordan constructed the very first concrete-like structures.

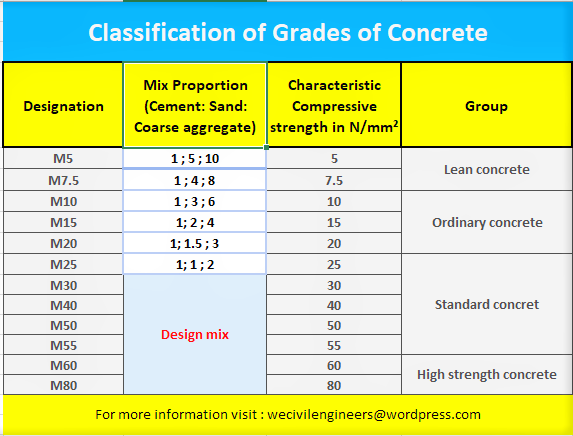

In civil engineering, making use of concrete as an architectural material is prevalent and popular for the value provided by concrete and also its convenience of applications. A criterion (regular concrete) concrete mix ratio is 1:2:4: 1 component concrete 2 components sand 4 parts accumulations The above materials are mixed to create a stone-like paste that solidifies over time and also is all set for usage in different frameworks (concrete contractor).

Conway Concrete Company Concrete Patio Can Be Fun For Anyone

Occasionally, auxiliary cementitious materials (SCMs) are included in concrete blends for key advantages like decreased permeability and also the general hardening of concrete. For example, fly ash concrete is recognized to be a stronger concrete with enhanced sturdiness. Let's obtain started with one of the most usual kinds of concrete utilized in building: Additionally called "common concrete," plain concrete is utilized with a mix ratio of 1:2:4 of concrete, sand, and accumulations.

Normal stamina concrete is a fast-setting substance of accumulations, cement, and also water. Absence of tensile strength makes typical toughness concrete appropriate for buildings or sidewalks that do not call for high tensile strength. Like ordinary concrete, regular stamina concrete includes comparable ingredients yet varies in strength with 10-40 MPa. Casting concrete into a multiple-use mold and mildew or form produces precast concrete that is treated in a regulated environment to acquire the preferred strength.

Another important aspect is the proportioning of the primary components so that the concrete holds various other participants in position. Treated precast concrete is delivered to building sites for creating complete precast frameworks, such as floorings and wall surfaces. Precast concrete frameworks are erected making use of cranes and special hooks are provided to raise them too.

Prestressed concrete is industrially developed concrete that involves positioning bars or tendons at the ends of an architectural unit prior to the application of concrete. The unit undergoes compression stress and anxieties during production to attain a higher architectural load ability and Visit This Link also increased toughness and Check Out Your URL tensile stamina. Prestressed concrete units supply faster building and construction as well as are commonly utilized for greatly loaded frameworks, such as bridges as well as roofs.

Not known Incorrect Statements About Conway Concrete Company Concrete Driveway

When currently created specialized concrete mixes are readily available, they simply have to be put at building and construction sites. In contrast to on-site concrete mixing, prepared mix concrete offers high precision and also decreases worksite complication. Admixtures like retarders are needed to protect all set mix concrete for use at building and construction sites as well much from the factories that produce and blend the concrete.

As the mix sets in 20-40 mins, it functions well for tasks like a fence, mailbox message, a tiny concrete slab, or any kind of other building task that requires rapid-setting concrete. Fiber-reinforced concrete is infused with macrofibers or microfibers to make it last much longer in severe weather like extremely chilly winters months.

Self-leveling concrete is appropriate for jobs that need flat, smooth surface areas. Conway Concrete Company concrete foundation. Reinforced concrete is a composite building material strengthened with steel bars positioned in the formwork throughout construction.

Known as "cellular concrete" and also "flowable concrete," light-weight concrete is made from numerous accumulations, such as clays, pumice, shales, as well as scoria. This easy-to-pour, self-leveling concrete with low thermal conductivity is used for making frameworks, such as flooring pieces, long-spanning bridge decks, as well as home window panels. Light-weight concrete is additionally used for securing steel frameworks as well as is made utilizing light accumulations, including: Increased clay, broadened shale, and also artificial More Info shale.

Some Known Details About Conway Concrete Company Concrete Driveway

Known as "absorptive concrete," pervious concrete's style enables for 15% to 20% voids of the volume of concrete. As pervious concrete is ideal for the flow of water, it is made use of in the construction of driveways and sidewalks to reenergize groundwater and also address drain problems.

Stamped concrete derives its name from marking or positioning a type of mold and mildew in addition to the solidifying concrete to achieve a decorative concrete coating. The surface area coating imitates the look of natural brick, floor tile, as well as stone surface areas, among others. Once the flooring has hardened, it is generally secured to enhance the durability of the concrete mixture.

Air-entrained concrete is concrete in which air is entrained (instilled) with the enhancement of a foaming representative such as foam or gas. The result is concrete with billions of microscopic air cells per cubic foot, with the entrained air making up 3% to 6% of the concrete. This method provides greater resistance to concrete against abrasion, wear and tear due to freezing and thawing, as well as scaling.

Usual air-entraining representatives include fatty alcohols, fats, and materials. Asphalt is a dark mineral that contains a mixture of hydrocarbons called "asphalts." Recognized as "asphalt" or "blacktop," asphalt concrete is the concrete of choice for sidewalk work and tasks, such as flight terminal paths, highways, parking great deals, roadways, and pathways.